Chandler, AZ -Rogers Corporation will be showing a range of engineered products at the Del Mar Electronics & Manufacturing Show (DMEMS), to be held on May 1st and 2nd at the Del Mar Fairgrounds in Del Mar, CA. Rogers will be at Booth #622.

The annual Del Mar Electronics & Manufacturing Show is a broad-based electronics show featuring exhibitors representing a wide range of technical concentrations, markets and industry segments. Rogers Corporation will have technical experts on hand to discuss its latest laminates, bonding materials, and foils.

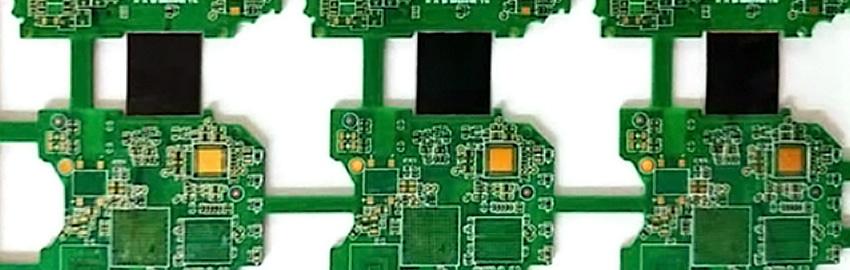

RO4835T™ laminates, offered in a 2.5 mil, 3 mil and 4 mil core thickness, are 3.3 Dk, low loss, spread glass reinforced, ceramic filled thermoset materials designed for inner-layer use in multilayer board designs, and complement RO4835™ laminates when thinner cores are needed.

RO4450T™ Bonding Materials are 3.2-3.3 Dk, low loss, spread glass reinforced, ceramic filled bonding materials designed to complement RO4835T and the existing RO4000® laminate family, and come in 3 mil, 4 mil or 5 mil thicknesses.

RO4835T laminates and RO4450T bonding materials exhibit excellent Dk control for repeatable electrical performance as well as a low z axis expansion for plated through hole reliability, and are compatible with standard epoxy/glass (FR-4) processes. These materials are an excellent choice for multilayer designs requiring sequential laminations, as fully cured RO4000 products are capable of withstanding multiple lamination cycles. RO4835T laminates and RO4450T bondply have the UL 94 V-0 flame retardant rating and are compatible with lead-free processes.

CU4000™ and CU4000 LoPro® Foils are sheeted foil options for designers looking for foil lamination builds and provide good outer layer adhesion when used with RO4000 products.

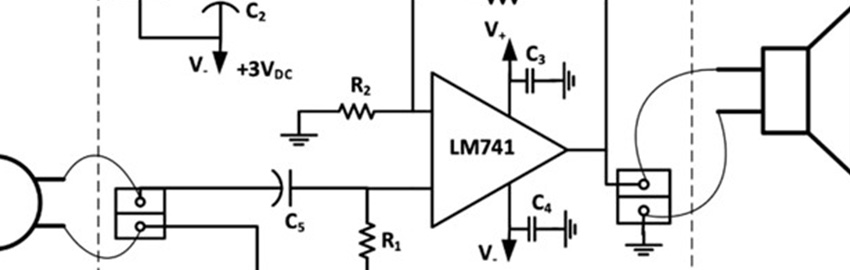

CLTE-MW™ Laminates

CLTE-MW laminates are ceramic filled, woven glass reinforced PTFE composites. CLTE-MW laminates were developed to provide a cost effective, high performance material for circuit designers. This unique laminate system is well suited for applications that have limitations in thickness due to either physical or electrical constraints. The seven available thickness options, from 3 mils to 10 mils, ensure that ideal signal-to-ground spacing exists for today’s 5G and other millimeter wave designs. In addition, a variety of copper foil options are available, including rolled, reverse treated ED and standard ED. Resistive foil and metal plate options are also available upon request.

CLTE-MW laminates are reinforced with spread glass, which along with a high filler loading, help minimize the high frequency glass weave effects on electromagnetic wave propagation. The woven glass reinforcement also provides excellent dimensional stability. Other key features of the laminates include low z-axis CTE (30ppm/°C) for excellent plated through hole reliability, a low loss tangent of 0.0015 at 10 GHz to enable low loss designs, and low moisture absorption of 0.03% to ensure stable performance in a range of operating environments.

Thermal conductivity of 0.42 W/(m.K) enables heat dissipation in aggressive designs, along with a high dielectric strength of 630 V/mil to ensure good z-axis insulation between conductor layers. The UL 94 V-0 flammability rating enables the use of CLTE-MW laminates in commercial applications.

CLTE-MW laminates are well suited for a range of applications including amplifiers, antennas, baluns, couplers, and filters. Applicable markets range from commercial and consumer to defense and aerospace.

About Rogers Corporation

Rogers Corporation (NYSE:ROG) is a global leader in engineered materials to power, protect, and connect our world. With more than 180 years of materials science experience, Rogers delivers high-performance solutions that enable clean energy, internet connectivity, and safety and protection applications, as well as other technologies where reliability is critical. Rogers delivers Power Electronics Solutions for energy-efficient motor drives, e-Mobility and renewable energy; Elastomeric Material Solutions for sealing, vibration management and impact protection in mobile devices, transportation interiors, industrial equipment and performance apparel; and Advanced Connectivity Solutions for wireless infrastructure, automotive safety and radar systems. Headquartered in Arizona (USA), Rogers operates manufacturing facilities in the United States, China, Germany, Belgium, Hungary, and South Korea, with joint ventures and sales offices worldwide. For more information, visit www.rogerscorp.com.