An iNEMI task group's review of components, laminates and equipment.

The conversion to lead-free assemblies and processing has been a disruptive and, in many cases, costly process for manufacturers. While many have managed the conversion, it is causing concern among manufacturers producing high-complexity, thermally challenging products that require high reliability over long periods of service.

Conversion to lead-free alloys - such as SnAgCu (SAC) - raises questions about the long-term reliability of lead-free materials as compared to standard SnPb formulas. (Many producers of high-reliability products will take the lead exemption in the short term, of course, but will eventually need to comply with it.)

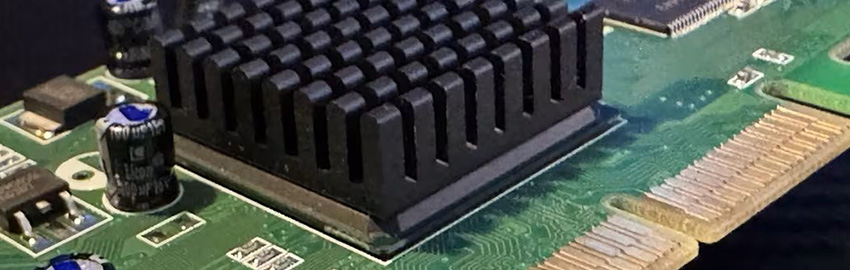

The broad component mix, board thermal properties and resulting thermal gradients across complex assemblies pose many thermal challenges and push current capabilities to the very edge of allowable limits. New soldering materials, maximum qualified component temperatures and primary attach or rework equipment are all sources of concern.

The iNEMI High-Reliability RoHS Task Force consists of OEMs and EMS providers whose products are characterized by long service life and high-reliability requirements. For these companies, maintaining product reliability is critical. The task force has developed several recommendations to address the primary areas of concern for lead-free processing of thermally challenging assemblies.

Components. For nonhermetic solid-state SMDs, it is imperative that component suppliers demonstrate compliance with J-STD-020C1 to the maximum exposure temperatures for primary attach and rework. (As specified in Table 4.2, these temperatures range from 245+0° to 260+0°C, depending on package thickness and volume.)

For other non-IC, MCM and SiP devices, iNEMI recommends that the procedures outlined in J-STD-020C be used for establishing moisture-sensitivity level (MSL) ratings and peak temperature survivability. In addition, certain industry specifications, namely IPC-95032 and IPC-95043, must be updated to reflect lead-free processing requirements. iNEMI task force representatives will work with standards committees to provide input and rationale for the proposed changes.

Small SMDs that will be attached to the bottom-side of a PCB and then passed through a wave solder or solder dip machine (full body immersion) should be qualified to JESD22A111.4 Components frequently wave soldered in this manner include small discrete components, SOT-23 and lower I/O leaded devices with pitches >=1.27 mm (0.050"). JESD22A111 specifies a max. exposure temperature of 260°C (+5/-0°C) for a maximum of 10 (+/-1) sec. for SnPb wave soldering. However, it has not been updated to reflect requirements of lead-free wave soldering.

Not only do SAC alloys melt at higher temperatures, they also do not wet as well as SnPb. Minimum hole-fill requirements for PTH devices (per IPC-A-6105) require increased solder pot temperature. The iNEMI task force recommends that max. exposure temperature be increased to a minimum of 265°C to accommodate new alloys used for lead-free wave soldering. To help offset this hotter temperature, the time required at 265°C can be reduced to 5 sec. minimum (laminar and chip wave combined). (This requirement is based on a wave solder pot temperature of 260°+/-5°C, a minimum wave solder conveyor speed of 3.25´/min. and a maximum wave contact distance [chip wave plus laminar wave] of 3.25".) The task force recognizes, however, that some thermally sensitive components will require special handling or fixtures if used on the bottom-side.

For BGAs or other area array packages, suppliers must meet coplanarity requirements (at room temperature) for the appropriate package outline specifications. Suppliers must also ensure assembly capability when packages are subjected to the max. reflow temperatures specified in Table 4.2 of J-STD-020C.

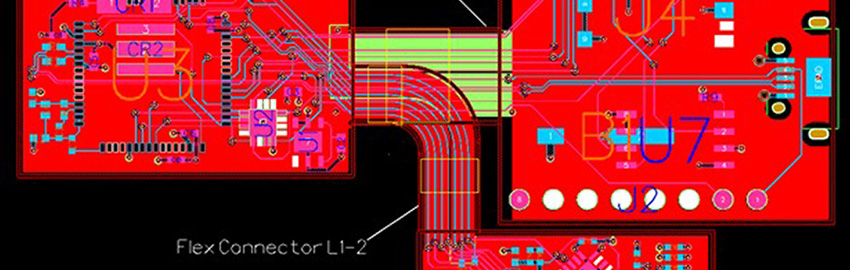

Laminate and PWB materials. While laminate materials used for SnPb assembly have been successful in less complex assemblies at lead-free processing temperatures, issues arise when using these materials for complex, thermally challenging products. Moving to higher temperatures increases materials sensitivities and several parameters - Td, Tg, CTE(x-y), CTE(z) - must be re-examined for reliability issues such as potential for delamination, peeling and warpage. More testing and evaluation is required before new laminate materials can be considered "lead-free compatible" for all applications in high-complexity systems.

After initial material selection, the manufacturer will need to validate acceptable performance of the materials in the use condition. Manufacturers must make sure that laminates can withstand both process temperatures and stress and will not be "invisibly weakened" in any way that would show up later in the field. Table 1 [PDF format] summarizes the test methods recommended to validate performance, including CAF and thermal/temperature cycling.

Equipment. The capabilities of primary attach and rework equipment are strained by higher thermal mass PWBs and assemblies, and it is difficult to stay within the minimum and maximum temperature limits imposed by J-STD-020C and JESD22A111. Process speed, peak temperatures, flux chemistry, solder pot contamination and soldering gas atmosphere are key areas of concern, and product and process designers need to work with equipment providers to understand and resolve these issues.

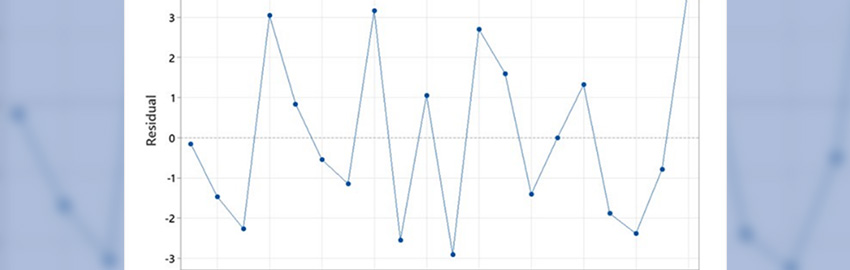

Reflow profiling studies using SAC solder for various thermally challenging products have demonstrated that the reflow oven speed must be slowed to guarantee a good solder joint (i.e., stay below the upper component body temperature limits defined by J-STD-020C while simultaneously staying above the minimum reflow temperature). However, this modification extends the overall processing time by 20 to 30% and puts significant additional strain on the soldering materials. Key issues from a materials perspective include:

- Ability of flux to handle higher temperatures at longer pre-heat times (135° to 200°C for 3 to 4 min.).

- Total profile times of 8 to 9 min.

Rework of large assemblies also challenges the equipment's ability to effectively heat the module being reworked while, at the same time, not overheating adjacent components. Techniques to improve reworkability include:

- Whole board preheat to reduce heatsinking effects of PWB power and ground planes.

- Improved adjacent component "shielding" from hot gas rework temperatures to prevent secondary reflow.

Preheating PWBs is also an issue when reworking PTH components. As discussed, the higher tin content combined with the slower wetting and spreading of SAC result in the need for higher solder pot temperature and longer contact time to achieve the same degree of hole fill. This, in turn, increases copper dissolution of the barrels and traces on the PWB and, therefore, requires tighter control of rework processes or equipment.

Manufacturers should consider adding process modeling, thermal and process profiling, or some type of overall process equipment verification instrumentation for all process equipment steps (e.g., placement, wave or reflow, and rework). These measures help ensure that process steps are within the control parameters needed to remain within the tight thermal process window posed by lead-free process materials.

The successful conversion to lead-free alloy systems for products that require high-reliability performance over the long term depends upon the entire supply chain doing its part to create, test and guarantee materials, components and process systems. As high-reliability products begin to make the conversion to lead-free, the industry needs to meet the remaining challenges of manufacturing these complex assemblies. The iNEMI High-Reliability RoHS Task Force developed these recommendations to provide direction to these efforts and is committed to working with the appropriate standards bodies to ensure that formal standards are updated to support evolving manufacturing needs.

Au: iNEMI's High-Reliability RoHS Task Force was finalizing its position statement on lead-free manufacturing requirements as this article went to press. For a copy of the final statement, go to www.inemi.org/cms/projects/ese/High_Rel_RoHS.html. PCD&M

Joe Smetana is principal engineer, advanced technology, at Alcatel and a distinguished member of the Alcatel Technical Academy; This email address is being protected from spambots. You need JavaScript enabled to view it.. Thilo Sack is principal engineer, corporate technology at Celestica, and cochair of the iNEMI task force; This email address is being protected from spambots. You need JavaScript enabled to view it..

REFERENCES

- IPC/JEDEC J-STD-020C, "Moisture/Reflow Sensitivity Classification for Nonhermetic Solid State Surface Mount Devices," July 2004.

- IPC-9503, "Moisture Sensitivity Classification for Non-IC Components," April 1999.

- IPC-9504, "Assembly Process Simulation for Evaluation of Non-IC Components (Preconditioning Non-IC Components)," June 1998.

- JESD22A111, "Evaluation Procedure for Determining Capability to Bottom Side Board Attach by Full Body Solder Immersion of Small Surface Mount Solid State Devices," May 2004.

- IPC-A-610D, "Acceptability of Electronic Assemblies," February 2005.