Building and maintaining what's said to be the world's largest CAD database requires strong relationships.

Keeping up with the increasing demand for new and specialized components is no easy task, but Ultra Librarian's team has proven up to the task – to the tune of more than 16 million components in its library and a quarter of a million unique downloads per month.

When we visited Ultra Librarian's office in Huntsville, AL, in early December, EMA Design Automation had just announced the library service's spinoff into a new ECAD-oriented company, Accelerated Designs, which was the original name of the company under its founder, Frank Frank, before it was acquired by EMA in 2016.

Ultra Librarian's parts database contains more than 16 million components.

Frank is still with the company today as chief architect, and oversees a team that specializes in the different aspects of maintaining its CAD library.

Ultra Librarian's employees add an average of around 35 parts per day to its library, but there are days in which the company builds hundreds of new parts, depending on the demand, Frank said.

UL has around 600 part templates that are used in the creation of new components, which significantly speeds the parts creation process as opposed to building each part from the ground up, he said.

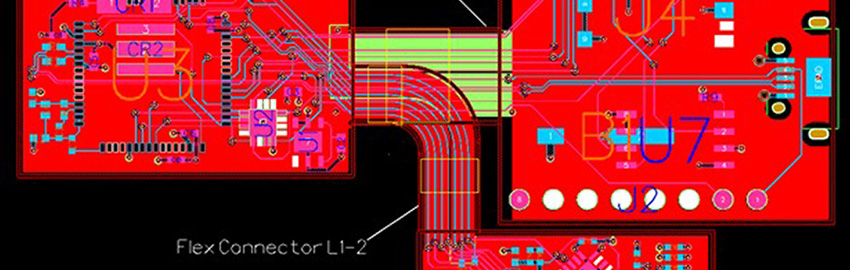

Once built, components are stored in Ultra Librarian's database, which supports 25 different CAD tools, and the schematics and models of all parts are available for free download by users.

One of Ultra Librarian's advantages is its ability to build a "superset" of a part, which means compiling all the relevant information about a part that could be needed in any of the CAD tools, and then exporting only those data needed for a specific tool.

"Part of what that template does is it adds in data for, let's say PADS, that's special for PADS, but it doesn't have to add it into Altium because Altium can't use it," Frank said. "We've got a data structure that allows us to put together as much data as we can, so that when it comes out, it's as complete as it can be."

Part of the company's services is also its ability to add components and parts based on user demand. Ultra Librarian receives around 80 such requests per day – and usually fills them within 24 hours before reaching out to manufacturers to entice them to add the part to their library.

"We've got a pretty smooth process to get it to the manufacturer," Frank said.

Those manufacturers also have their own part libraries, and anyone looking up a part on Ultra Librarian's database can see if the part was built in-house by the UL staff or added by a manufacturer.

Ultra Librarian's data are stored in a vendor-neutral format, meaning that the company stores the relevant data from the many CAD tools it supports and prevents inconsistencies across the different CAD types. Most of its parts are also built using UL's desktop software, which also helps make sure components are consistent across the different tools. When appropriate, parts are built to the IPC-7351B standard, and symbols are built based on the ANSI Y32.2-1975 standard. The library also generates 3-D models, built to the STEP-file format, ISO 10303-21, of each part based on its footprint.

As EMA Design Automation is exclusive distributor of Cadence's OrCAD products in North America, the recent announcement of Ultra Librarian's spinoff into a CAD-agnostic company should permit it better to connect to other CAD users, Frank said.

"It will allow us to be viewed as more neutral," he said. "It will allow [EMA] to take some of the other products they have and sell them to more than just Cadence customers."

The key to Ultra Librarian's success has been its ability to maintain strong relations with manufacturers, and making sure those manufacturers' components are up to date in the library and available for users to find and use them.

"We have a good relationship with a lot of these people, and that's what makes everything work," he said. "The manufacturers definitely want their files spread out so people can design their parts with them."

Ultra Librarian chief architect Frank Frank credits the company's good relationships for its continued success.

AI-Based Modeling

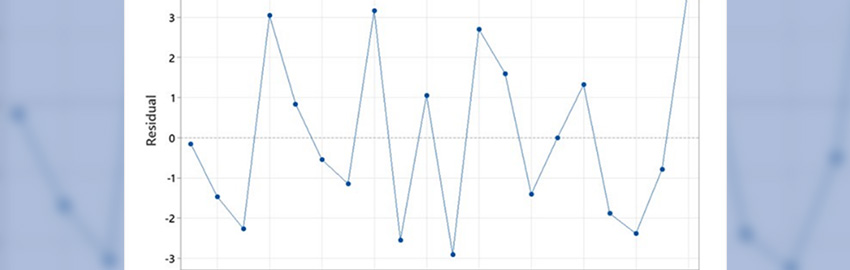

To keep up with the increasing need for speed in developing CAD models, Ultra Librarian has developed an AI-driven engine that takes advantage of its experience in CAD modeling to drastically decrease the time needed for development.

The project started as a curiosity for Frank, who said he wanted to see if AI could be used to generate components, and has turned into a new service that will soon be available for users.

The model is designed to work by pulling information directly from datasheets provided by a manufacturer, which required training the AI tool to identify an order table, pin data and other needed information on its own.

The Ultra Librarian team has been training the AI model using the multitude of CAD models available in its database, and the tool has continued to improve its efficacy as it learns, Frank said.

"The goal is to take all the parts on the datasheets, rather than just the part that was requested, and take as much as that information as possible rather than us having to type or scrape it," he said.

After gathering that data, the AI tool is then able to build the part's footprint, with all its data, symbols and a 3-D model, for entry into the component database.

The company announced the AI modeling engine late last year, and previewed the technology for visitors at PCB West 2023.

Frank said the tool will soon be available as a free beta, and once it starts to hit its full potential, it could cut the time needed for CAD modeling by as much as 20 to 30 times when compared to manually finding and inputting the data.

"I have a lot of confidence that we'll be able to get there," he said.

Tyler Hanes is managing editor of PCDF/CIRCUITS ASSEMBLY; This email address is being protected from spambots. You need JavaScript enabled to view it..