Sunrise, Florida, September 21, 2020 – Nano Dimension Ltd. (Nasdaq: NNDM), a leading Additively Manufactured Electronics (AME)/PE (Printed Electronics) provider, announced today that effective September 14, 2020, Dr. Joseph Kaplun has been appointed as the Company’s Chief Technology Officer – Materials and Vice President of R&D and Product Development.

Until September 2020 Dr. Kaplun was the CTO and co-founder of Phononics Technologies Ltd., a partnership between the ELTA/Israel Aerospace Industries (IAI) and ICDAT (Israeli Center of Advance Diamond Technology). Prior to that, Dr. Kaplun has spent 25 years with the IAI as the CTO, co-founder and Acting General Manager of Gal-El, unique GaAs, GaN, InP and MEMS devices and MMICs FAB. It is a partnership between the ELTA/IAI and the Weapon Development Authority (RAFAEL) in Israel. Dr. Kaplun was responsible for technology development, production’s process failure analysis and yield improvements, maintenance and engineering supports, as well as serving as VP of Engineering, Engineering Manager, Chief Technologist, Head of Thin Films Department and Thin & Thick Films Engineer.

In the Technology Development Center of The Silicon FAB in USSR, Dr. Kaplun was the Head of Ion Processes Department, Senior Process Engineer of Ion processes section, PECVD, RIE, Ash process, Sputtering, Evaporation, and Ion implantation.

Dr. Kaplun earned his Ph.D. from NPO “Center of Sciences” in Moscow and B.Sc. & M.Sc. in Material Science in Microelectronics from the Moscow Institute of Electronic Technique, Zelenograd, Material Science Department. His publications include books about High Vacuum Technology, courses in Vacuum Technology Basics and Statistical Process Control as well as articles on BCB etching Process using High Density Plasma, Critical dimension improvement of plasma enhanced chemical vapor deposition silicon nitride thin films in GaAs devices, High Power Ka – Band PIN Diode Technology, Investigation of Contact Metal Stacks for Submicron GaN HEMT, Origin and elimination method of parasitic gate leakage current for AlGaN/GaN hetero-structure field effect transistor, Re-configurable MMIC: on-wafer fine tuning capabilities and Stepper-based integrated process on wafer pieces.

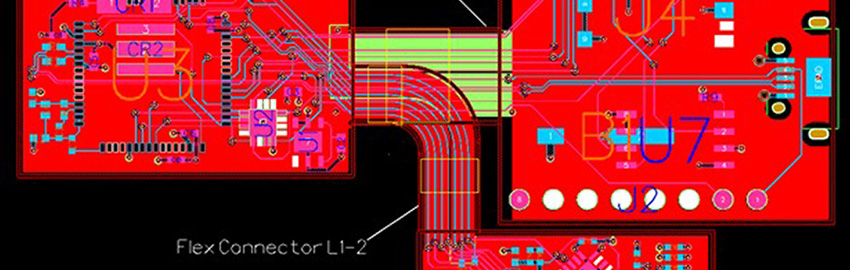

“Nano Dimension’ products incorporate some of the most exciting technological evolution and opportunities that I have ever encountered, insomuch as proven thick layers printing capability for very advanced electronic devices,” commented Dr. Kaplun. “The company’s 3D printing system enables prototyping and fabrication that is not achievable otherwise at such competitive price and performance. Leading multi-billion dollars defense contractors, government agencies and research institutions on four continents are only the first early adaptors of what I envision to be a paradigm shift in fabrication of PCB, interposers, chip packages and compact, light 3d-multi-layered capacitors, inductors, transformations and additional long line of electronic discrete devices that can be realized only by this technology. I know most of the players in this industry, and they are far behind still. I am glad to take a part of this technology revolution”.

“Joseph is a highly important addition to our product development and multi-disciplinarian technology team,” said Yoav Stern, CEO and President of Nano Dimension. “His proven leadership track record and reputation in delivering breakthrough products precede him. He is the right person in the right time for the right team. He will lead our R&D and engineering group in performing our product road map plans.”

Mr. Stern added, “As I have mentioned before, the long-term effects from West-East trade wars and Covid-19 on our industry will be an increase demand for technology like ours, which enables prototyping and short-runs production of Hi-PEDs (High-Performance Electronic Devices) on-the-ground in the Western Hemisphere, at prices and time-to-market that are competitive and in some cases superior to traditional multi-billion dollar PCB manufacturing industry in the Far-East. Temporarily, assuming three to four quarters until the effects of COVID-19 will subside, we have changed our priority: Only lightly investing in the commercial side of the business (sales and marketing). Simultaneously, we are accelerating our product and technology development, improving our competitive position. This initiative will be led by Dr. Kaplun, as we intend to further develop our technology and improve present inks and printer performance as well as create next generation machines and materials earlier than market expectations.

PCB West Virtual 2020 has more than 125 hours’ worth of technical sessions on printed circuit design and manufacturing available through Oct. 12. pcbwest.com