An Ohio community college breaks the mold with an applied bachelor’s degree in electronics manufacturing.

In my three decades in electronics engineering, perhaps the only thing that never changes is the need for more skilled workers. No matter the state of the economy or the geography, having knowledgeable and competent engineers and operators is always critical, and there are never enough of either.

But while the tension is notable between industry and academia over who is responsible for preparing the next generation of workers for specific tasks, some schools are quietly taking the lead by putting in place programs that include true hands-on training in printed circuit board manufacturing.

I’m talking specifically about Lorain County Community College. Lorain is in Northeast Ohio, about 30 miles west of Cleveland.

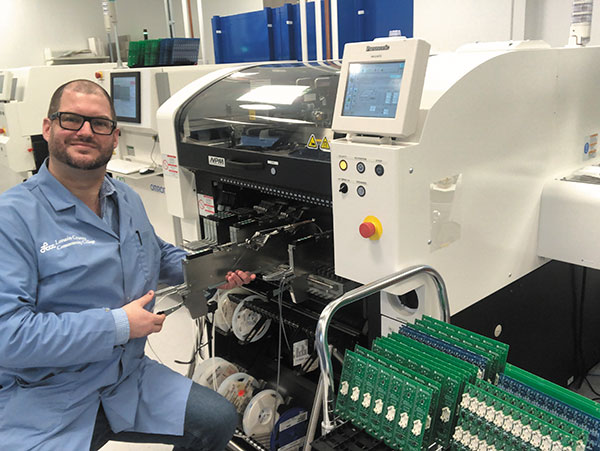

In 2012, LCCC launched an associate’s degree program to train students in electronics manufacturing. In 2018, LCCC became the first community college to offer an applied bachelor’s in microelectronics manufacturing, and two years ago, it formed the Manufacturing Electronics & Rework Institute for Training, or MERIT, the hands-on training lab. Last spring, the program graduated its first students.

Figure 1. Lorain County Community College saw the first students in its applied bachelor's degree program graduate in 2021.

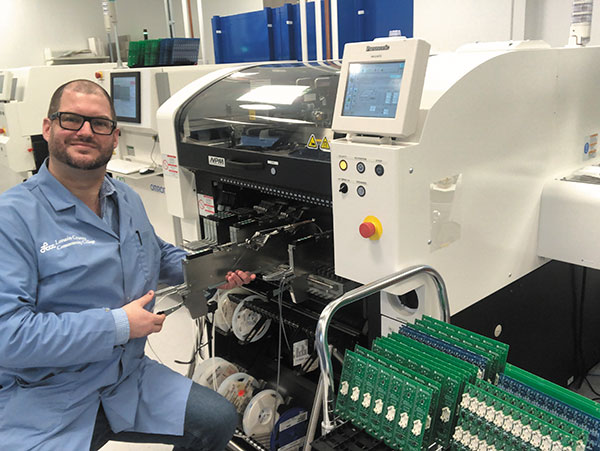

Johnny Vanderford, the director of MERIT and an assistant professor of MEMS at LCCC, and Courtney Tenhover, program developer in engineering, business and information technologies, explained how the program came about and detailed its successes.

Mike Buetow: There’s so much I want to ask about the LCCC and MERIT programs. Whose idea was this in the first place?

Johnny Vanderford: It was the industry’s idea. About eight companies in 2012 got together and said, “We’re short on workforce, and colleges aren’t graduating people who can work for us starting from the beginning. They all require potentially a year’s worth of training, on-the-job equipment handling, and everything like that, and nine times out of 10 they are either not skilled or just not a good enough worker to keep with the team.” They said, “What we want is a college that is going to actually step up and help us with our workforce shortages.” Several of these supporting companies were being hit by what’s called the Silver Tsunami, which means their workforce is growing gray hair, and their generation is retiring to places where drinks are served with little umbrellas in them. They’re taking all the knowledge they gained from their companies and leaving, and there’s nobody fresh coming in or graduating from college with the hands-on skills. Nobody coming out of universities knows how to solder, or knows very little, as in, “Yeah, I’ve seen it on YouTube,” or “I’ve done it once.” It just wasn’t good enough for these companies. They were short on workers, so in 2012 they said, “Can somebody help with this?” That’s when I heard about it, and I said, “Yes, I want to join the team here at Lorain County Community College to teach this associate’s degree” called microelectromechanical systems, or MEMS, and it took off from there. It’s all about helping companies find skilled workers, while also having a training and education system that’s meant to train people in an affordable college [program].

MB: I would agree folks coming out of engineering school today may know very well how gas moves in a chamber, for example, but if you put them in front of a convection reflow oven, they have no idea how to set up a profile or make the machine run. What goes into launching a program like this? Did you have to do much market research to convince LCCC of the need?

JV: When we launched, what we first looked at, ironically, were the job markets that were asking for people. We went to Indeed; we went to LinkedIn; we went to the Surface Mount Technology Association’s website. We asked, “What do companies want right now? What do they want for their technicians? What do they want for their operators?” And we were literally hit with waves of job requests that just weren’t being met. It seems like a pretty easy step to say, “Let’s ask the state for a little bit of funding to buy some capital equipment. Let’s get buy-in from our college to be able to say, ‘Let’s launch a class with this,’ and let’s get a professor to teach some classes.”

They hired me initially as an adjunct instructor, while I was working for a packaging company called Smart Microsystems, which makes chips, and initially it was [conceived] as part-time work. We started with three students in 2013. We started training them in ESD, what it means to ground yourself, and why it is important. We started them with soldering training, doing through-hole and surface-mount components. We showed them pieces of equipment: “This is how you use a microscope.” A microscope is a legitimately difficult tool to use, but if you’re going to be working with 0402 and 0201 components with lead-free solder, you better know what you’re looking at and how to use the tools available to you. That first year, we had three students and eight supporting companies that were asking for people. All three of those students were hired before they finished their associate’s degrees.

The next year, we had five students, and all five were hired before they finished their degree. Once we had a student who said, “I’m an artist. I’m really good at painting.” This student in particular could do calligraphy on rice. It’s a hobby I thought was dead a long time ago. Wouldn’t you know it, she’s really good at soldering. Now she’s soldering ribbons in ZIF connectors for the biomedical industry for cardiovascular systems. It started with employers who told us, “This is what our needs are,” a small handful of students, and some funding from the state to get us laboratory equipment and training equipment so we could train and educate these students to get careers in the industry.

Figure 2. Johnny Vanderford was tapped from industry to lead LCCC's microelectronics manufacturing program.

MB: Let’s talk a little more about the program curriculum, and then we can get into the facilities and the equipment. What are the prerequisites for matriculating students?

JV: If you could balance a checkbook, that’s pretty much all the requirements you really need. [laughs] I’m serious, though. You need high school sophomore-level English, high school math equivalency, and then you’re in. We aren’t teaching rocket science. It’s not advanced calculus or anything like it. It is hands-on skills that involve using tweezers in one hand and a soldering iron in another, while looking through a microscope. It involves practice of near-surgical skills with the knowledge of material handling, as well as working in a quality manufacturing system. That’s what it ultimately involves.

The whole program curriculum, in order to get in and start taking classes, you could start as long as you could pass high school math, high school English. We have students in the degree program right now who are coming from art backgrounds, nursing, business, construction, welding, administration. We have folks who are working in one industry and going through JobsOhio for funding to get education to get into a new career field. We have a retired letter carrier from the US Postal Service and a retired corrections facility officer from the Lorain County prison. One of our students is a radio broadcaster, and he knows how to solder circuit boards and manufacture them in high volume.

The entire curriculum was made by our industry supporters. Everything in our current curriculum is meant to get folks trained in what I would call a blue-collar degree. There’s no calculus, no quantum physics, no crazy science stuff. It’s all skills. On day one, [we teach] “this is ESD; this is how you ground.” Day two: “This is a soldering iron. Let’s start with 1206 resistors.” That’s where we started. The associate’s degree was built entirely based on our employer needs, so we could train folks who may come from all over the place. These are non-standard students who come in not just out of high school, although we do get a good amount of them out of high school. There are military veterans using the GI bill. There are newly divorced parents trying to work for the first time because they haven’t had a job for a while. There are folks coming from all different backgrounds, and with a little bit of practice and some hands-on training, they’re able to work for and expand at these companies. After years of doing this, we have over 80 industry supporters within this program, and to this day everyone who has ever been through the associate’s degree program and graduated from the associate’s degree program has been hired into work at our 80 industry supporters. That’s a 100% hiring rate. There aren’t a lot of universities or colleges that can say that. I’m proud to be able to say every student who graduated from here with [either] the associate’s or bachelor’s degree has been hired.

MB: For clarification, the MEMS degree – the applied bachelor’s degree – is a two-year program that’s on top of an associate’s degree?

JV: Yes, the associate’s degree is very heavy in the areas of what I would call hand solder training. We certify all our students to IPC J-STD-001, in addition to them taking three other classes to where they’re soldering with an iron, with a hot air rework station using a microscope, doing through-hole and surface-mount lead and lead-free, teaching them the difference between the two.

We start every student with lead because that’s the easy stuff. Then we show them lead-free and they’ll [say], “This is kind of hard!” “Yeah, and you have to learn this because you might work for a company that only does lead-free soldering.” The bachelor’s degree feeds off the associate’s degree and basically trains them in high-volume PCB production. By the time they finish their associate’s degree, they’ve got a truckload of hand solder training, a little bit of PCB design, as well as some PCB prototyping experience. Most important of all is we require every student in our associate’s degree program to be employed for at least 300 hours in order for the students to get their degree and in order for LCCC to continue receiving funding from the state. All state colleges get funding based on graduates of their programs.

Every time a student graduates from our program, the state gives us funding. They give funding like that to all the other bigger universities, but [those schools] have tuitions astronomically higher than where we are. Our tuition is $3,900 a year for a full-time student. It’s the lowest tuition for any associate’s or bachelor’s degree in the state of Ohio. We’re dependent on the state share of instruction, that funding coming in from the state. The logic is, if a student hasn’t been hired by the time they get their associate’s degree, not only are they not going to get their degree, the college won’t get funding to continue the program, and maybe the college, if they do this enough, should start to look at offering degrees that do get career experience and get people hired.

In fact, every student who goes into our bachelor’s degree is required to have work experience in order to gain entrance into the program. That’s unique criteria for us. We have companies that are hungry and interested for more students from our program, but the bachelor’s degree has classes in addition in high-volume PCB manufacturing, how to operate a stencil printer, pick-and-place, reflow, an AOI … not just how to operate it but how to program it, how to design in CAD and very specifically to design for manufacturing, put in fiducials, put in mounting holes, make sure you have test points on your surface board, put on rails so it can sit on a conveyor without problems. Then we go into additional sidetracks like electronics and testing, how to use the multimeter, how to use the power supply. We’ve got classes in mechanical design, how to do AutoCAD, SolidWorks GD&T, and blueprint reading, and classes in quality, which include ISO 9001 Yellow Belt Six Sigma Lean manufacturing principles, statistical process control, gage R&R. I didn’t put all this in … the companies wanted it, so we put in all this information so these companies could get training to their potential workforce and get a whole pile of potential workforce. The companies let Courtney know about job descriptions, and Courtney is the funnel between students getting résumés out to the company, and companies that have job requests go straight to Courtney.

MB: So quite literally, you don’t get paid until the students get paid.

JV: Yes, we don’t get paid until the students are hired in, which makes us uniquely like training and education and somewhat recruiting as well.

Courtney Tenhover, Program Developer, Workforce Development

MB: Courtney, within the MEMS program is something you call “earn and learn.” What does that mean?

Courtney Tenhover: Earn and learn was the program we developed so students can essentially earn while they learn. We worked with employers to begin this program, and students can work with an employer three days a week and have their classes scheduled on two days a week, so all their classes can fall on those two days, leaving them available for the employer for those three days a week, so they’re not just offering four hours here and there. It’s more of a consistent schedule for both the student and the employer. It helps employers minimize the time they spend to recruit someone, and hopefully the student has a fulltime job at the end of completion, so all the time employers spent working with the student and training them was money well spent because now they have a fulltime worker with the skills they requested to Johnny.

MB: So, someone could start as a student and start working at a company outside of LCCC, or they could actually be already employed and start taking classes at LCCC in the MEMS program?

CT: That’s correct. We’ve worked both ways, where it’s students whom we are helping find employment or incumbent workers who want to upskill their skills within this area.

MB: You offer courses in assembly, plus the opportunity to learn fabrication and design to the students. Do students do all this in MERIT, or is there actually any classroom instruction?

JV: There are some lecture-based classes and discussion, but the model is the only way to learn how to ride a bike is to get on the damn bike and ride it. You can watch a YouTube video of someone riding a bike, but that doesn’t mean you know how to do it. If you want to watch a YouTube video of someone soldering 0402 components or operating a pick-and-place system or x-ray, that’s grand. Let’s sit you down on the equipment to do it. As of right now, we have three training laboratories in the core classes of our program. One of them is a solder laboratory that has soldering irons, hot air rework stations, microscopes, ESD testing equipment, electronic testing equipment, and that’s where we train folks in the earliest stages of the program. Typically speaking, before they are employed with one of our employers, a student usually has to work with us for six months to a year’s worth of training and education. The demand is so high for people, however, that we’ve had some students hired literally within seven to eight weeks of our program. The companies are like, “Wait, they held a soldering iron before?” And we say, “Yeah, actually we’re doing 0603 resistors and polarity-specific devices.” “Yes, that’s exactly what we need. Everyone else we’ve ever hired can’t spell solder, let alone do it.”

Our second laboratory is very similar, except it’s in a Class 10,000 cleanroom. Several of our sponsor companies make biomedical devices and have a need for people who know how to do electronics manufacturing within a cleanroom environment. Some also do things beyond typical PCB soldering. Several companies do PCB fabrication, so we train students on photolithographic processing, ferric chloride chemical etching, development and chemical handling, and expose them to some of the material processes it takes to actually fabricate a board.

We also have equipment in our cleanroom for wire bonding and die attach for chip-scale packaging, and in the case of our class, we do a lot of chip onboard processing, so we wirebond them to a board to create a functional circuit board. On top of that, we have soldering, microscopes and what I would call semiautomatic introductory equipment for doing SMT prototyping and low-volume production. We have stencil printers that are more or less mechanical. We are printing on 5" x 5" stencils. It’s not big, but we are using our funding appropriately to be able to give people training, education and skills to get hired.

We have four semiautomatic pick-and-place systems where the operator has to operate it with their hand on a gantry, but they also have to load the feeder. The feeders have a button where if you push the pickup tool nozzle down onto the button, it feeds fresh parts forward. There’s a vacuum nozzle the operator has to control with a button in their other hand. We’ve got a three-zone reflow oven that’s sitting on a bench that teaches them. This is a belt-driven oven just like what you see in the industry, just 10 times its size.

In our bachelor’s degree, where we also do a lot of our training at MERIT, we have a high-volume Panasonic stencil printer and fully automated Panasonic pick-and-place system with 48 feeders both front and rear and a 20-tray loading system. It has two heads: one with 16 nozzles, one with three nozzles. The throughput is something like five or six parts every second. We have an Omron screen print inspection system and an AOI that we’re doing all the programming on. We have an eight-zone reflow oven that we teach M.O.L.E., what it is they will put forward through the temperature profile. We have a Creative Electron x-ray microscope [with which] we train students on how to look for solder points. BGA rework tools by Manncorp that we teach how to line up a BGA. Every student who takes that class hates BGAs at the end of it. “Why are we using these? They are such a pain to be able to put on!” We tell them this is what’s in modern design. People want more functionality in their electronic devices, so you have to know what to do in case it doesn’t go right.

Figure 3. At LCCC, students learn the intricacies of rework and hand soldering.

MB: Wait until they see QFNs.

JV: Yeah! We make them put down QFNs, and they all hate them afterwards. And wait until you see a truckload of these boards with it!

In MERIT, we have a lot more of the high-volume-based equipment for training the students in their nighttime classes. Usually when they’re taking classes there, they’re all working during daytime shifts or on the Train Ohio schedule in different places. Then they swing by us and take classes at night, which allows us the luxury of being able to offer workforce training through MERIT during the daytime. If a company wants to hire our students or put a job description on us, we will do it. We have had about 12 or 15 companies from outside in the last year or so. They’ll say, “Could you train our folks if they fly out there?” We say, “Yeah! We will train them. We will teach the same thing we’re teaching in our associate’s and bachelor’s degrees. We will teach in short-term private seminars where it is still hands-on; they still can see the equipment. We had a company recently that hired three people who have never done electronics manufacturing. They’ve never seen a soldering iron. They have no idea what a pick-and-place system is. They were surprised to see solder paste is made of small particles. “I thought it was just some gray mush.” We take a microscope and say, “Look: There’s the solid pieces. Let’s actually reflow it so you can see what this looks like afterward.” We’re able to train them so they get the same hands-on training as the day student but in a shorter timeframe, albeit at a higher cost since it’s a private class.

MB: Was all that equipment donated, or was that part of your startup costs?

JV: We bought it. The college asked for funding originally from the state of Ohio to get some of the equipment for our associate’s degree. The state had kind of a strict requirement. They said we need employer support to do this. We said, “Sure, we’ll get employer support. We’ll make it so students have to be hired as part of our program.”

Then the state gave us funding for our first laboratory, and eventually we expanded into an additional solder laboratory. Once we became the first community college in the state to have its own bachelor’s degree in microelectronics manufacturing, the college put money toward buying this equipment and since, for the funding to be able to get this third laboratory of high-volume production equipment. But it’s so awkward because we get companies that say, “Well, what kind of research are you doing? What kind of prototyping are you doing? What kind of product are you building?” We tell them the same thing every time: “The product is the people we are pumping out. We have students coming out of the program who are trained how to do this. If you want to send your workforce, we will train them.” We will train a new workforce coming in, so they have a clue as to what’s going on, and using our college education appropriately. We’re not heavily involved in any kind of research or prototyping. In fact, we’re not involved in prototyping at all. We have companies that say, “Can I use your equipment to build something?” We have a fully automated line. We could, but we say, “Here’s our company supporters who are already hiring our students. We will train your folks, but if you’re looking for other companies, there’s a whole bunch in our area who can do this type of work.”

MB: All that hands-on learning means you have to have good teachers. Tell us a bit about the instructors. Does the faculty draw on its own industry experience? How did you recruit staff?

JV: Courtney and I were just talking about the mechanism we have, or maybe the lack thereof right now. We’re young. We’re only eight years old, and we feel we are unique in the United States. I’m not aware of a lot of other places that are doing what we do, and I’d love to know if there are. I’d love to be able to get some feedback from folks in other places who are doing something similar because what we’re doing is working. So, if it does exist, can we talk to you, and if it doesn’t exist and you’re interested, can we share what we’re doing so we can spread this out?

The faculty and staff who work with us typically are coming from two places. The first place is from our industry supporters and places where they’ve already had working experience. If they’re going to be a part of our educational system, they also have some degree. If they want to teach bachelor’s degree classes, they have to have a master’s degree. If they want to teach associate’s classes, they have a bachelor’s. We have to find a nice mix of people who have a degree and someone who has experience. I want someone with more experience. Occasionally we get some Ph.D. who calls. I ask, “What kind of work experience do you have?” and they say, “Well, I’ve got 30 publications and this and that,” and when I ask what companies they worked for, the answer is zilch. So, they typically don’t make their way over here.

The second area is kind of a homegrown mechanism. We have several student workers and technicians who are graduates of this program who see an interest in helping other people find work and employment. They’ve had some work experience, but they are ultimately interested in being able to help other students, help run our equipment, help clean the laboratories, help train other people.

We had a couple of student workers, and they didn’t have anything to do at the time. I said, “Go downstairs and load every feeder up,” and they sure did. They went down, got a tape and reel and a bill of materials and loaded every single feeder. “Now what?” they asked. I said, “Tear it down and do it again,” because they have to know how to do it, and they have to look good while they’re doing it, to show other students how you do it. A lot of times it’s just practice to be able to do it. As the program goes, we are somewhat of a smaller program. Including [me] and Courtney, we have four instructors and three student workers and a couple of laboratory assistants or techs. It’s not the mightiest of programs, but we’re growing with the natural way other companies will want to hire people and just kind of watching how it goes to see how we can provide them a better workforce.

Figure 4. Tearing down and restocking the placement feeders is all in a day’s work for LCCC students.

MB: How many degree students can you take each year?

JV: That’s a good question. Prior to Covid we were ready to expand to either 36 or 48 students every single year. Covid took a nasty toll because two things happened simultaneously. First, the college asked a lot of folks to teach anything they could online from home. The problem was I tried to get soldering irons into some of the students’ homes, and we just couldn’t do it. We require a lot of hands-on training, so the students have to be on campus. That alone led to some difficulties in training. The other problem was the companies that were manufacturing biomedical electronics – specifically the hospitals – all of a sudden had second and third shifts that popped out of nowhere. Courtney and I have never seen so many job requests from companies. These students literally have a huge amount of job opportunities available to them, should they be interested in taking a position.

Now we’re taking I think … 24 or 36 students. Due to Covid restrictions, we have to keep the class sizes limited. We have to keep everything kind of limited, but once it starts to change a little bit more and we’re allowed to increase the capacities, we expect to go back to a full set of classrooms the way we were in 2019 where we had all our classes maxed out for years.

A lot of students see this program leads to careers. It’s affordable, and in some of the cases these students are really interested in what they’re doing. They’re really interested in working with their hands, working with local companies, working with the materials and equipment. We’re expecting after maybe a year or so, this goes back up to maybe 36 to 48 students every single year, but we do expect it to climb beyond that. The job requests are just huge right now, and we don’t have enough students to provide all the job requests that are there, but are we going to work toward getting them those students and getting the most workers? You bet.

MB: You mentioned that when the program began you had eight corporate partners and now something like 80.

JV: Yes, that’s over the life of the program.

MB: What’s the nature of that partnership? Are they advisors? Companies that are helping place your graduates? All of the above?

JV: In many ways all of the above. These companies that support our program, our industry partners, are first and foremost our advisors. We don’t want to teach students or train people in things that won’t lead them to careers. In the early parts of our program, that was part of it, so we had a couple of companies that did fabrication processes and wanted more chemistry, more chemical handling within the program. So, we took physics out as a science class and introduced chemistry to create a fabrication class with students doing chemical processing on bare printed circuit boards. We originally had calculus in our program and, to quote Greg Vance of Rockwell Automation, “I don’t need someone to do a derivative. I need someone to work with my team, work with my equipment, and make my company money. We make circuit boards, and that’s what I want the program content to be.” So, we kicked out calculus. The highest level math class in our program is a statistics class, which is appropriate for the discipline of what we’re training people to do: to be designers, manufacturers, technicians, operators, and manufacturing engineers. In some of the cases, doing integrals and differential equations is not going to give them skills necessary for that particular career. Are those classes worthless? Maybe not. They’re just better for other degrees.

Ultimately where a lot of these industry partners come into play is in hiring our students. It’s partner or perish. We either get our students hired to work with the company, or we cease to exist. We’re very interested in the feedback from our industry partners and to hear what it is a student should know in order to get hired, what we can give them in terms of that experience.

CT: We also understand that not every employer can hire someone all the time, so we invited players to even just provide feedback and hope in two years from then they could hire someone. Their feedback has been part of the process, and employers can review résumés, provide mock interviews, provide degree feedback. We want employers at the table whether they can hire someone today or in two years.

MB: The program itself hypothetically could be, or the model at least could be, packaged and offered at other community colleges around the country. Is that a fair assessment?

JV: To add onto that, in addition to 100% of all students who graduated being hired 85% of our current students are working as part-time workers or interns, or in some cases they are full-time workers while they take part-time classes. It all depends on the companies and the student schedule. That ability to have what we’re doing duplicated elsewhere is a big factor of what we want to talk about.

In fact, we’re currently working as part of a grant the Air Force provided to the state of Ohio called ADMETE [Assured Digital Microelectronics Education & Training Ecosystem]. ADMETE is basically there to train students to work in trusted and assured microelectronics solutions. It is based on six colleges working as an ecosystem together to create degrees and create training opportunities. One of the ones that’s working with us is Wright State University. Vance Saunders there is working on a computer science and engineering program where students are learning how to solder circuit boards as a skill that would be beneficial for them working at a company. So, Vance is asking, “Can you share some of the content with us?” and our response is, “Here you go.” Then we say, “What kind of equipment are you using? Here is the exact equipment we have.” Now Vance has the third problem of who’s going to do it, and we say, “Send us your folks. That’s what MERIT was built for. MERIT is built to train not just workforce but other institutions in the areas of electronic manufacturing. Send us your workforce or your faculty, your staff, your grad students, your adjuncts, or whomever you want.” They get hands-on training and short-term classes. They go back to Wright State, which now has a laboratory with the equipment that’s going to train people to work, educational material that’s based on what industry wants them to be trained in, and a training mechanism where they could send others to MERIT in case somebody graduates or goes somewhere else. That together makes for a well-rounded hands-on training ecosystem that any university in the entire United States could do.

If readers are interested in more about what this is, the website is lorainccc.edu or lorainccc.edu/merit. There’s more information on the curriculum and videos, some success stories, and information about the degree program and workforce training.

Mike Buetow is president of PCEA; This email address is being protected from spambots. You need JavaScript enabled to view it..