Champagne Voiding Causes and Tests

Corrective measures include adjusting the solder paste chemistry and reflow profile.

Corrective measures include adjusting the solder paste chemistry and reflow profile.

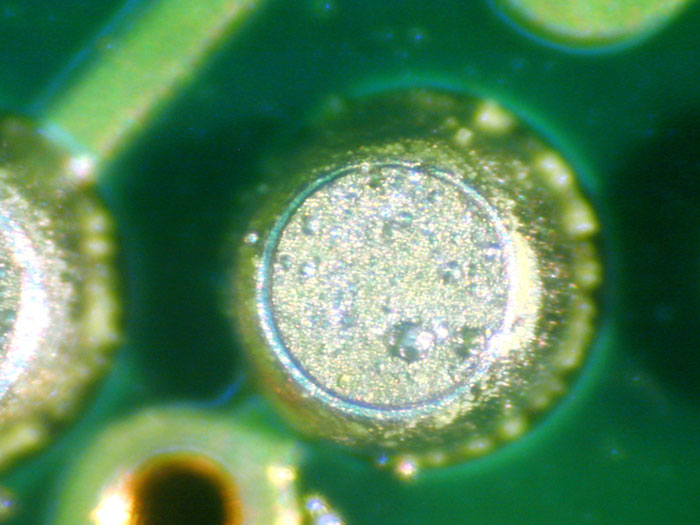

Voids in solder joints are not uncommon after reflow soldering and can be easily detected using x-ray. Champagne voiding is related to hundreds of very small voids seen at the solder joint-to-surface pad interface (FIGURE 1). When they occur in reflow voiding, the cause may be related to the solder paste and profile. The voids will be seen in the bulk of the solder joint or near the top of the joint at the component pad interface.

Figure 1. These are called champagne voids because they resemble bubbles in the solder.

Champagne voiding was originally seen on silver-coated boards, and related to organics gassing during reflow soldering. This problem was overcome by chemistry suppliers. However, the author has seen a few recent cases at one automotive supplier.

FIGURE 2 shows a ball pull test conducted on a Dage heated stage to examine pad cratering between PCB pads and laminate. This has also been used by the author to examine voiding on joint interfaces. It may be possible to compare the degree of voiding at the interface with joint strength. The ball pull test can be valuable to assess the impact on joints. The test method was originally designed to examine pad cratering defects seen on BGA packages with brittle laminate.

Figure 2. A ball pull test can be used to examine voiding on joint interfaces.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the Defect Video of the Month, presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

is a consultant at the National Physical Laboratory (npl.co.uk); This email address is being protected from spambots. You need JavaScript enabled to view it.. His column appears monthly.