Zuken Innovation World enlightens users on the firm’s latest software updates.

CORONADO ISLAND, CA – During the past 35 years, end-to-end design has been a relatively backburner topic, but Zuken has designs on making that a thing of the past.

In doing so, the PCB software developer is attempting to “harness” what many see as today’s Holy Grail of system design.

Of course, if it hadn’t been for the abundant 30-minute technical sessions over the course of two days in mid April, attendees at Zuken Innovation World might be excused for feeling they were on vacation.

Zuken pampered attendees on an island off the coast of San Diego. The weather was perfect as we enjoyed a welcome reception and ate lunch outside at the Marriott next to the water. The annual Ladies’ Dinner and the early morning opt-in walk around the island served to strengthen the family-style bonds the company successfully develops. And, yes, there were gourmet cupcakes during one of the afternoon breaks.

Inside, Zuken experts shared updates to their flagship software as they celebrated their 40th anniversary, complete with an ongoing “expert bar” for live demonstrations. As a third-time attendee to this event over the past five years, the high level of passion each Zuken team member exudes is striking; they care about their customers and what they do, and each event is as relevant as the last.

In a standout welcome presentation, Bob Potock, Zuken’s vice president of marketing, noted the changes that have taken place over nearly four decades of automated design – and those that haven’t. Although EDA started in 1981, he noted, today “we’re still talking about the 2D PCB-centric design tool chain.

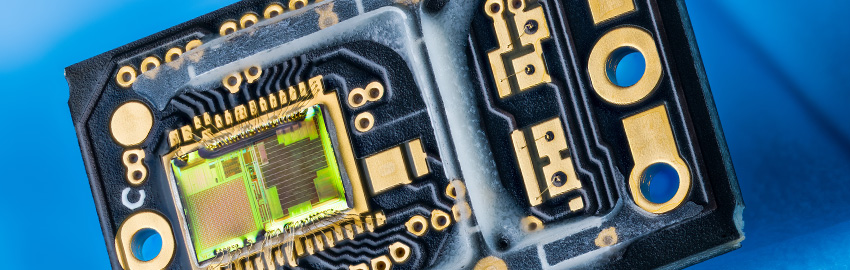

“The introduction of FPGA is a huge industry driver,” he said, as it propels high-density packaging. “We have to consider multi-board designs now; we have to consider wire and harness. Product packaging is now a competitive advantage,” and “electronics has to accommodate the package. It’s not the other way around anymore.”

One of the most dynamic areas of change is design methodology, Potock said. “People don’t design with chips anymore; they design with functional blocks.”

With chip package co-design, “emerging advances go beyond EDA, but EDA has to accommodate them.”

Potock believes the business landscape is transforming, and “design processes should enable better decision-making.” Business benefits of this include corporate IP protection and modular design improvements, including quality and lower costs.

Zuken’s answer is 3D product-centric design, including the supply chain, engineering data management, hardware architecture design, 3D chip package board, multi-board connectivity, wire/harness, and 3D MCAD/ECAD.

“In the next year, Zuken will focus more on how PCBs and harnesses are connected,” he said.

With a product-centric design methodology, its best to start with the requirements: hardware architecture design, functional design, PCB planning, space planning, parametric validation, and a corporate library.

Potock shared a list of CR-8000 2016 release highlights, including DG and DfM viewers; chip package co-design; the inclusion of IBIS-AMI and LTSpice; the management of constraints at the block level; and 3D step model exports.

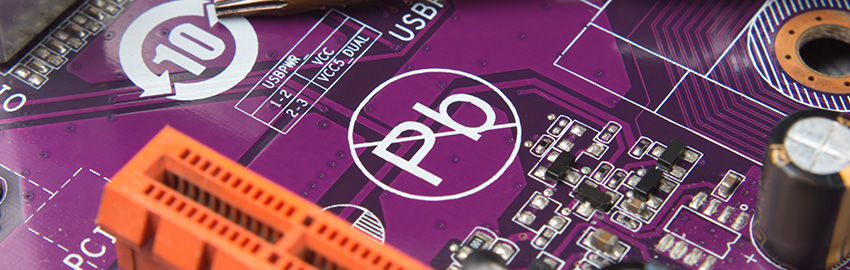

Also new in 2016 is Zuken’s partnership with Accelerated Designs, which has provided 7.2 million components for CR-5000/CR-8000. DS-2 Espresso has customizable library and data management capabilities; assignment of 3D parts in the library; and the ability for 3D flex bending and checking. (“Flex boards are becoming more and more popular,” Potock said.) It also provides concurrent PCB design, allowing up to five users at once on a board.

Concurrent PCB design was a running theme throughout the event. In Design Force’s latest iteration, the number of clients is visible, Zuken senior applications engineer Steve Watt said. “It’s fairly interactive,” providing “good feedback to users about what each other is up to.

“If one user picks up a component,” and another user tries to pick up the same component, “user two will get a warning.

“Whoever saves last wins,” Watt joked.

He stressed assigning multiple designers can reduce cycle time.

Design Force also accommodates 2D and 3D design simultaneously, fellow senior applications engineer Craig Armenti explained. The 2D and 3D windows are visible side by side. In Design Force, you can drag tracks and drag and drop parts. “You don’t have to open menus; just interact with the canvas, and it will intuit what menu you need.”

And if you’re moving from Board Designer to Design Force, you can use the same library. Designs are compatible, Armenti said. “You can bounce back and forth as you learn Design Force; the two can coexist.

“You can do MCAD and ECAD interference checks earlier in the PCB design cycle,” he added in a separate presentation. There’s “a lot of data exchange between MCAD and ECAD. We need to help break down the brick wall.”

The value of true 3D parts, Armenti said, is the “true representation of what parts are going to look like and how they go together.”

Zuken’s latest innovations since the 2015 event in the same location were impressive, backing up what CEO Kent McLeroth shared with PCD&F during a casual conversation at lunch: Zuken invests substantially in engineering.

It shows.

Other Show Highlights

Electronic data transfer. Why do we need IPC-2581, the consortium-led standard? Gary Timmons, design engineer senior staff at Lockheed Martin, explained: “ODB++ is missing industry standardization. … IPC-2581 is basically replacing ODB++ as an independent XML language. There’s no Gerber sent out, no drill sent out.” It’s “one file” and “done.”

Timmons added, “One file format makes everyone’s job so much easier.”

Accolades. McLeroth presented the Zuken USA 2016 Innovation Award to Cummins Electronics. The firm came to Zuken in 2011 looking to start its design processes from scratch, and “they actually did it,” McLeroth said. Criteria for the award included innovation in product development, design processes and utilization of Zuken products.

EMC and power integrity. EMC rules of thumb may apply or they may not, according to Ralf Bruening, product manager/senior consultant at Zuken’s EMC Technology Center. “There’s no silver bullet for EMC issues,” he said. “Use common sense.”

He said to visualize and analyze signal current paths, locate parasitic antennas and crosstalk paths, and be aware of potential EMC sources.

“Identify and understand coupling mechanisms,” Bruening urged, because “EMC is getting more important every year.”

In a separate power integrity primer, Bruening said, “Frequencies are going up, and design cycle times are going down. Modern PCBs comprise complex CPUs and fast memories. Switching currents and peak voltages increase significantly.”

The goal, he said, is to “provide a steady voltage level while supplying charge across all required frequencies.” The challenge is to create low inductance paths.

“I propose concurrent PI analysis within PCB design. Power supply noise is a major design issue. Problems can be avoided by properly designed PDs,” Bruening concluded.

Catch Bruening’s Power Intensity and Decoupling Primer for PCB Designers at PCB West in September.

Inspiration. In a riveting keynote, Jeff Salz, adventurer anthropologist, weaved exciting tales of circumnavigating Lake Titicaca, extreme rock climbing, and his perilous stint as a Gaucho with inspirational messages, one of which applies well to Zuken: “I would posit adventure is the same as innovation,” he said. If that’s the case, Zuken has adventure covered in spades as it looks ahead to the next great revolution in PCB design.

Chelsey Drysdale is senior editor at PCDF/CIRCUITS ASSEMBLY; This email address is being protected from spambots. You need JavaScript enabled to view it.